For us at Selva Coffee, it’s of the utmost importance that everyone on our team experience the entire process of our coffees - not only from production to export; but also to learn about the ways that the roasters take each individual lot and make magic with different roast profiles and brewing methods.

I [Nazareth] had the opportunity to visit Denver and Minneapolis to discover new and different parts in the coffee chain.

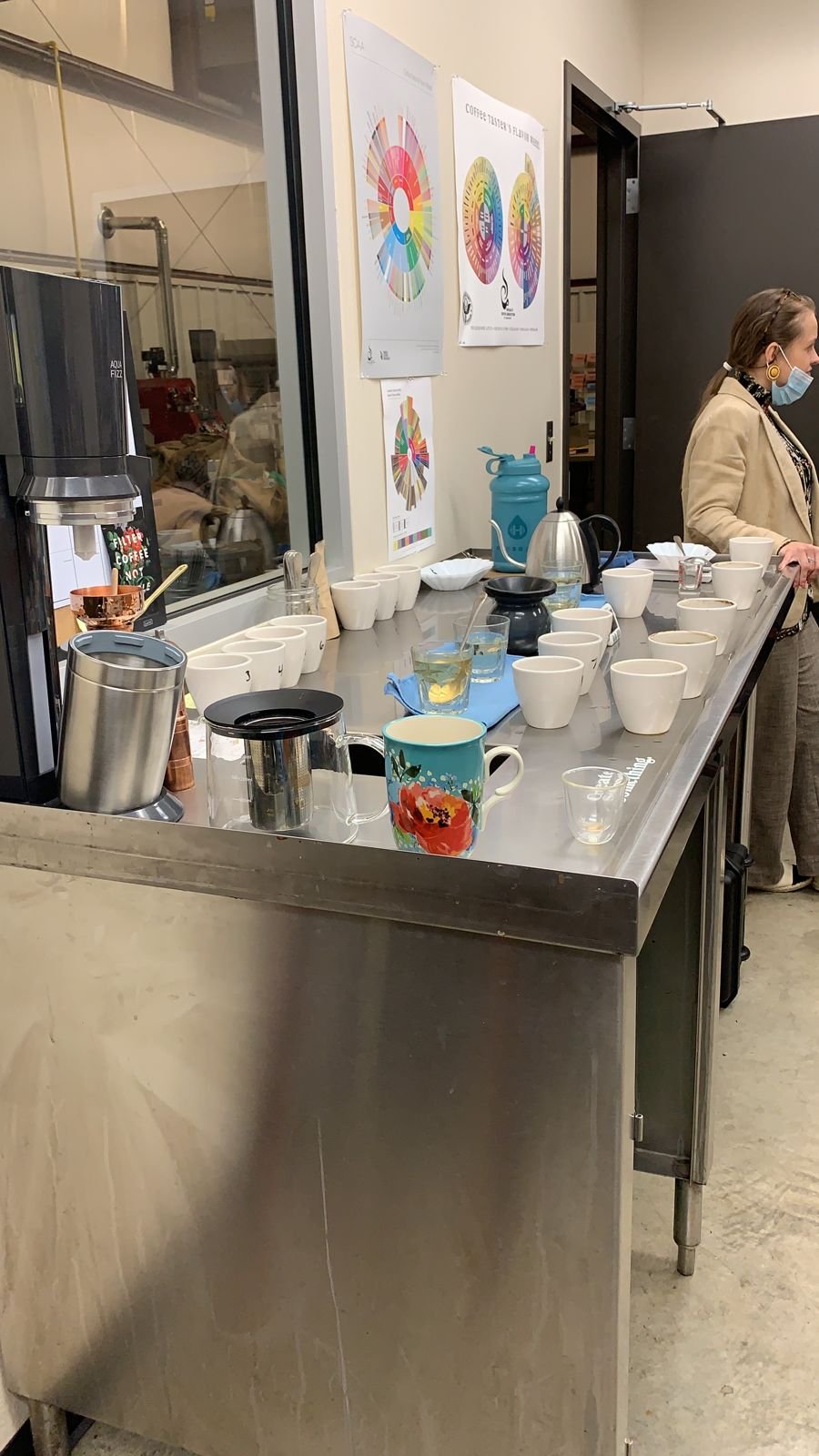

For example, the importers that help us to bring the best coffees to our customers around the world. During my time in Minneapolis, I spent a few days with the Trabocca team who received me in a very nice way and showed me the dynamics of their work. We also got to cup many of their coffees that come from different origins in the world, which are very different from what we are used to in Costa Rica.

I learned a lot about the different quality controls they utilize. This allows me to take advantage of the visit and provide feedback on my work in the cupping lab back in Tarrazu. Now, as a team at the Selva Lab we can improve harvest after harvest.

During my stay in Minneapolis I had the opportunity to participate as a volunteer in the Qualifiers for Brewers Competition. I got to see, first hand and for the first time, the different ways in which the participants develop and look for the most interesting way to prepare their coffees. In this event I had the opportunity to meet people who have many years of working in this industry and some people that are just interested in learning too.

For people it was very interesting to have a person from another origin like Costa Rica in these events. That made me feel special!

After spending a few days in Minneapolis, we went to Denver. I met roasters that we have had a relationship with for some years. Such as, Queen City, Servant, Sweetbloom, Sonder, MiddleState, Strava and also visited others roasters that are not buying coffee yet from Costa Rica. All showed me their way of working, their different roasts and I was able to learn about the type of market that they work for. The different commercialization of their coffees. Also it was very interesting that they take their time to designing a menu and experimenting to bring out the best highlighting. One of the most important fact of all of those roasters is that all of them support important social causes, such as projects run by women, which makes me feel proud and motivates me to continue working with them.

Español:

Para Selva Coffee es de suma importancia conocer el proceso de nuestros cafés desde su producción hasta la manera en que nuestros clientes hacen magia con estos.

Tuve la oportunidad de visitar Denver y Minneapolis para conocer partes importante de la cadena del café como lo son los importadores que nos ayudan hacer llegar nuestros mejores cafés a nuestros clientes alrededor del mundo en este caso tuve la oportunidad de compartir con el equipo de Trabocca, los cuales me recibieron de una manera muy agradable y me mostraron la dinámica de su trabajo y catamos muchos de cafés que provienen de distintos orígenes, los cuales son muy diferentes a los que estamos acostumbrados en Costa Rica.

Aprendí sobre los distintos controles de calidad, esto me permite aprovechar y retroalimentar mi trabajo en la sala de catación para que como equipo en Selva Coffee podamos mejorar cosecha tras cosecha.

Durante mi estancia en Minneapolis tuve la oportunidad de participar en un voluntariado en el Brew Competition, conociendo la distintas formas en que los participantes se desenvuelven y buscan la manera más interesante de preparar sus cafés, en este evento tuve la oportunidad de conocer a personas que tienen muchos años de trabajar en esta industria y así como algunos también están interesados en aprender.

Para la gente fue muy llamativo tener a una persona de otro origen en esos tipos de eventos, siempre abiertos a aprender y compartir conocimiento y experiencias.

Después de estar unos días en Minneapolis fuí a Denver, donde conocí a tostadores con los que ya tenemos relación desde hace algunos años, podemos mencionar a Queen City, Servant, Sweetbloom, Sonder, Middle State, Strava, también visité a otros tostadores que aún no compran de nuestro café.

Todos ellos me recibieron y me dieron un trato genial, me mostraron su manera de trabajo, sus distintos tuestes y pude conocer el tipo de mercado al que van dirigidos, me llamó la atención las diferentes formas de comercialización de sus cafés, donde toman su tiempo para diseñar un menú, de experimentar para llevar el mejor resultado y calidad a sus clientes, también debo resaltar que la mayoría apoyan causas sociales muy importantes y entre estos uno de los más especiales es el apoyo a proyectos que son dirigidos por mujeres, el cual me hace sentir orgullosa y me motiva a seguir trabajando con ellos.

Para mí esta experiencia fue increíble, porque a pesar de venir de una familia productora, en años pasados nunca había tenido el suficiente interés de aprender o conocer del mundo del café

En el año 2021 fui aprendiendo, siempre siendo apoyada por mi familia, pero principalmente por mi papá que siempre quiso que yo continuara con el legado familiar que con tanto esfuerzo y años ellos han podido obtener.

El equipo de Selva Coffee también me brindó la oportunidad de ser parte de su equipo y de compartir conocimientos en esta experiencia.

Ver el trabajo y gran esfuerzo que cada productor pone durante el año desde los cuidados en sus fincas, hasta la parte del procesamiento y beneficiado, me hace sentir muy orgullosa de como en otro país sus cafés están siendo disfrutados y sus historias son llevadas a cada uno de los clientes.